MFC9070 3 Masiteshoni Thermoformer

Tsatanetsatane wa Makina

Kugwiritsa ntchito

Makinawa adapangidwa kuti azipanga zotengera zapulasitiki zotseguka, monga thireyi chakudya, thireyi pulasitiki, thireyi zodzikongoletsera, chithuza, clamshells, mbale ndi zinthu zina pulasitiki.

Mapepala Oyenera

PVC, PP, PS, OPS, PET, APET, PETG, CPET Etc.

Mawonekedwe a Kapangidwe

1.Mechanical, pneumatic ndi magetsi ophatikizana, zochita zonse zogwira ntchito zimayendetsedwa ndi PLC.Touch screen imapangitsa kuti ntchitoyi ikhale yosavuta komanso yosavuta.

2.Pressure Ndi/Kapena Kupanga Vacuum.

3.Mmwamba ndi pansi kupanga nkhungu kupanga njira.

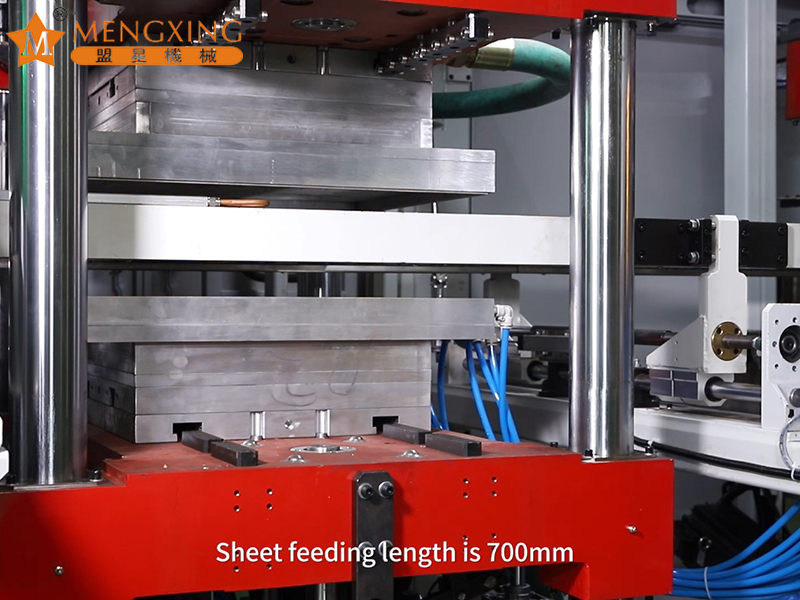

4.Servo motor kudyetsa, kudyetsa kutalika akhoza sitepe-zochepa kusintha.Liwiro lalitali komanso lolondola.

5.Upper & m'munsi chotenthetsera, magawo atatu Kutentha

6.Heater yokhala ndi dongosolo lowongolera kutentha kwanzeru, imangopereka zowongolera zowotchera munthu.Kutentha kwachangu (3 min kuchokera ku 0-400 digiri), sikudzachitidwa ndi magetsi akunja.

7.Kupanga ndi kudula unit mold kutseguka ndi kutseka kulamulidwa ndi servo motor, mankhwala amawerengera okha.

Ntchito yoloweza pamtima ya 8.Data imatha kusunga 120 seti ya data yomwe ikuyenda.

9.Stacking mtundu: pansi stacking / Robot Stacking.

10.Feeding m'lifupi akhoza synchronously kapena paokha kusintha njira magetsi.

11.Oven adzakhala basi kukankhira-kunja pamene pepala pa kutentha, Air kuthamanga sikokwanira.

12.Automatic lubrication system.

13.Quick mold kusintha dongosolo, Auto mpukutu pepala Kutsegula, kuchepetsa ntchito katundu.

Technical Parameter

| Kutalika kwa pepala (mm) | 540-940 | |

| Makulidwe a pepala (mm) | 0.1-1.5 | |

| Kutalika kwa pepala lalikulu (mm) | 800 | |

| Kupanga chiwopsezo cha nkhungu (mm) | (Mmwamba) 170, (pansi) 170 | |

| Mphamvu ya Mold clamping (tani) | 80 | |

| Malo opangira Max (mm2) | 900 × 700 | |

| Malo opangira ma Min (mm2) | 500 × 400 | |

| Kupanga kukula kwa nkhungu (mm) | 500-900 | |

| Kutalika kwa nkhungu (mm) | 400-700 | |

| Kuzama kwambiri / kutalika (mm) | 155/155 | |

| Kudula nkhungu (mm) | (mmwamba) 170, (pansi) 170 | |

| Malo odula kwambiri (mm2) | 900 × 700 | |

| Kudula mphamvu (tani) | 100 | |

| Kuzungulira (nthawi/ min) | Kuyika kwa Robot Max17 Pansi Stacking Max40 | |

| Kuziziritsa | Kuziziritsa madzi | |

| Kupereka mpweya | voliyumu (m3/ mphindi) | ≥2 |

| Kuthamanga kwa Air (MPa) | 0.8 | |

| Pampu ya vacuum | Busch R5 0100 | |

| Magetsi | 3 gawo 4 mzere 380V50Hz | |

| Mphamvu ya heater (kw) | 145 | |

| Mphamvu zazikulu (kw) | 190 | |

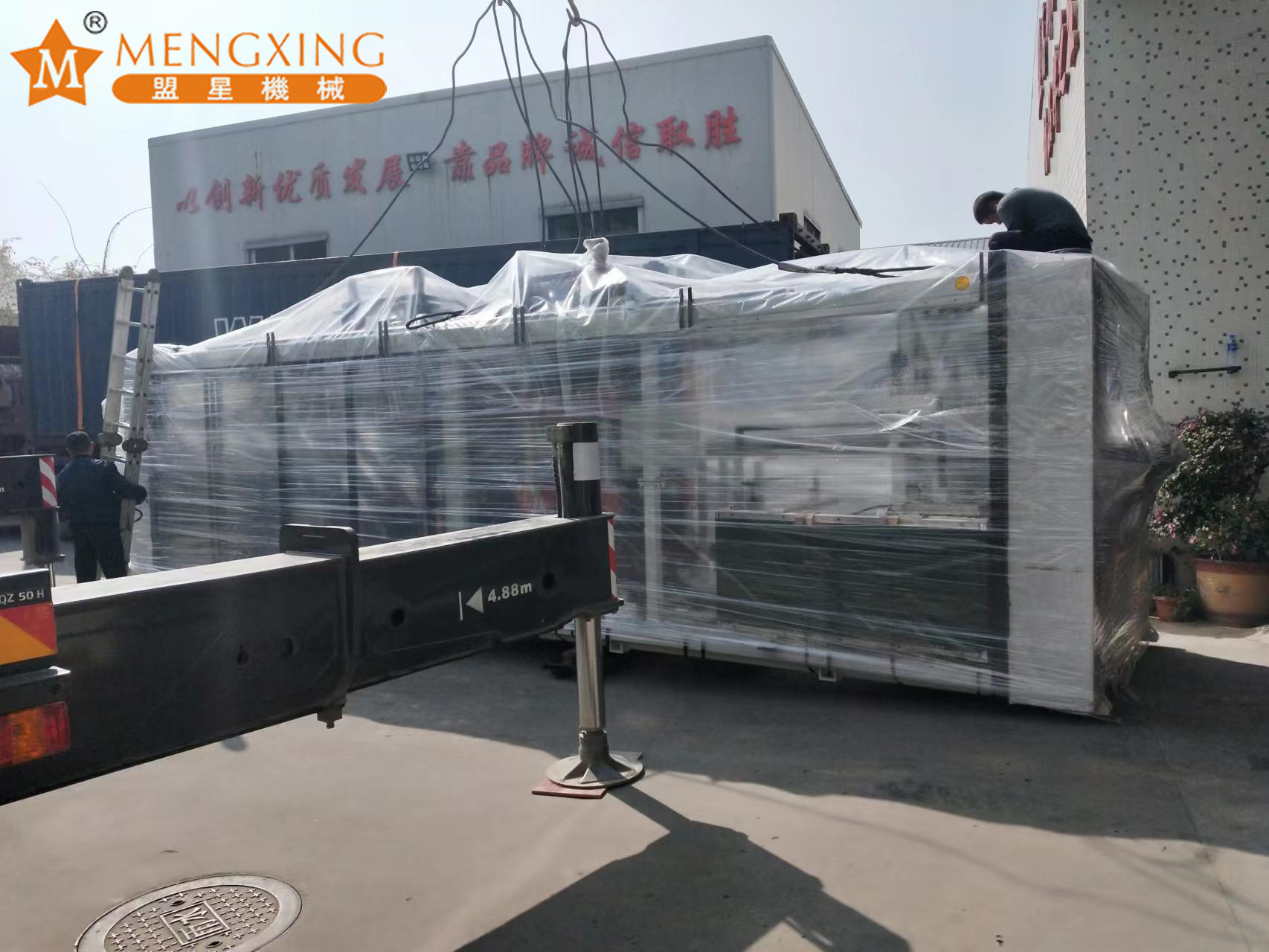

| Kukula (L×W×H) (mm) | 13400×3000×3230 | |

| Kulemera (T) | ≈25 | |

Zida Zaukadaulo

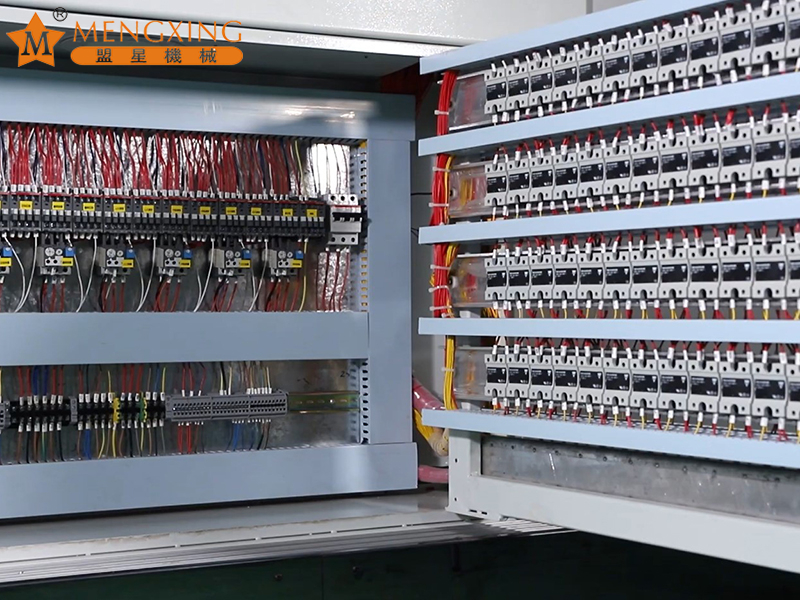

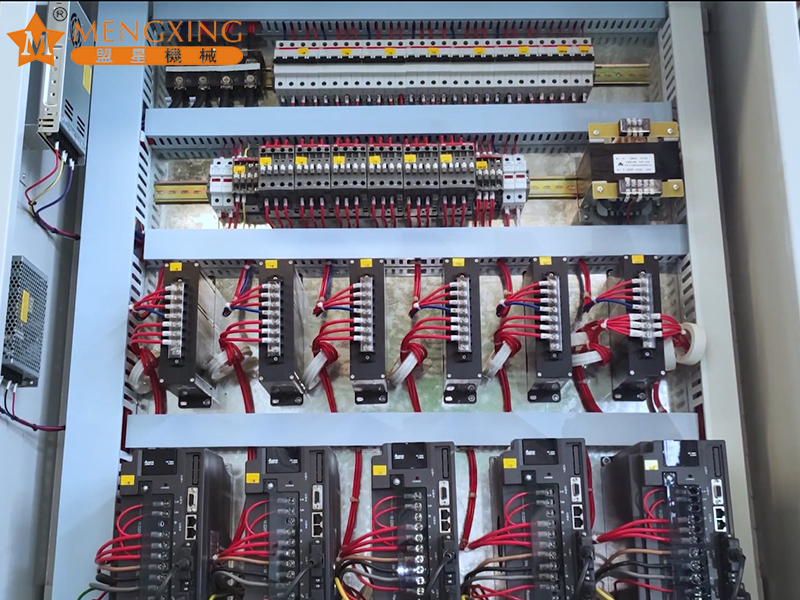

| PLC | Taiwan Delta |

| Touch Screen Monitor (15 ″inchi / Mtundu) | Taiwan Delta |

| Kudyetsa servo galimoto (5.5kw) | Taiwan Delta |

| Kupanga mmwamba/pansi nkhungu servo galimoto (7.5kw/7.5kw) | Taiwan Delta |

| Kudula/kutsika nkhungu servo galimoto (7.5kw/7.5kw) | Taiwan Delta |

| Kuyika servo mota (2kw) | Taiwan Delta |

| Heater (288pcs) | Germany Elstein |

| Contactor | Switzerland ABB |

| Thermo Relay | Switzerland ABB |

| Relay | Germany Weidmuller |

| SSR | Switzerland Carlo Gavazzi |

| Pampu ya Vuta | Germany Busch |

| Kudyetsa Chain | Italy Regina |

| Automatic Lubrication System | Taiwan ChenYing |

| Electronic pressure sensor | Taiwan Delta |

| Mpweya | JAPAN SMC |

| Silinda | JAPAN SMC & Taiwan Airtac |

Bwanji kusankha ife

Makina athu agulitsidwa padziko lonse lapansi.Kuchita bwino kwamakina kumathandizira kuti makasitomala aziwakhulupirira komanso kuyamikira.Tikupitirizabe kuyika ndalama mu kafukufuku ndi chitukuko mu thermoforming ndi kupanga makina.Ndife apainiya aku China komanso mtsogoleri pantchito iyi.Nthawi zonse amayesetsa kukhala wopanga padziko lonse lapansi.Timalandilanso anzathu ochokera kumayiko ena kuti agwirizane nafe ndikukhala nthumwi zathu kuti tiziyendera limodzi msika ndikutumikira makasitomala athu bwino.

Zogulitsa zamakono, zizindikiro zachuma zafika pamtundu wa dziko, wofanana ndi mtundu wakunja wakunja, mu 2006 kupyolera mu ISO9001: 2000 Quality Management System Certification, misika yogulitsa kwambiri yapakhomo ndi yakunja, yodalirika kwambiri ndi ogwiritsa ntchito.

Zitsanzo Zithunzi

Zithunzi za Container